Introduction: Why is the Cleanliness of the Air in the Operating Rooms A Matter of Life and Health?

Nosocomial infections (HBIS), also known as nosocomial infections, pose one of the most serious threats to patients in healthcare settings around the world. This problem is especially critical in operating rooms, where invasive procedures significantly increase the risk of infection. The air saturated with microorganisms, dust and other aerosol pollutants is one of the main ways of transmitting pathogens, which is confirmed by the constant attention to the organization of “clean rooms” and “aseptic zones” in healthcare.

Modern medical standards and regulations require not just ventilation, but the creation of a strictly controlled air environment. Traditional ventilation systems based on air mixing are often unable to provide the level of cleanliness necessary to prevent the spread of airborne diseases. This is where specialized solutions such as laminar ceilings come to the fore. These ventilation and air conditioning systems don’t just provide comfort.; They are a critical piece of infrastructure that directly affects patient safety and the effectiveness of medical procedures. Investments in such systems are considered not as additional costs, but as fundamental investments in the protection of health and compliance with strict sanitary standards, which in turn strengthens the reputation of the medical institution and optimizes its operational activities.

Laminar ceilings are an advanced, high-tech air purification system designed to create and maintain ultra-clean areas in operating rooms, intensive care units, and other critical medical facilities. They provide a directed, uniform flow of purified air that effectively displaces pollution and minimizes the risk of contamination. Climate PROF Kazakhstan LLP, as the official representative of the Polish Klimor plant, is proud to offer these innovative solutions – NSL laminar diffusers – for medical institutions throughout Kazakhstan.

What is Laminar Flow and How Does It Protect Patients?

A simple explanation of the principle of unidirectional (laminar) air flow

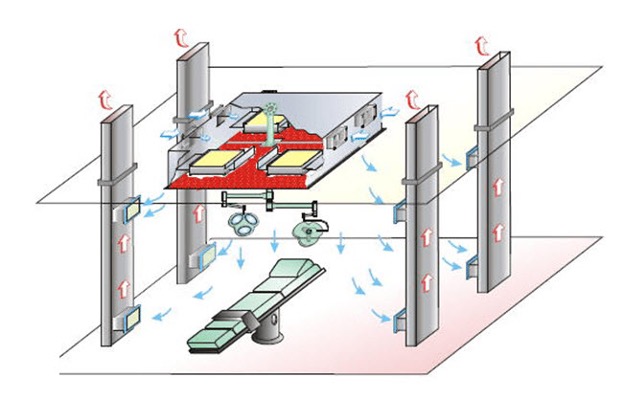

Unlike conventional, “turbulent” ventilation, where air moves chaotically, mixes and creates vortices, laminar flow is characterized by unidirectional, uniform movement of all air particles parallel to each other. This principle creates a kind of “air piston” that constantly moves from top to bottom, expelling any contamination, including bacteria and microbes, from the protected area.

How does this create a “sterile air curtain” over the operating area

This controlled flow of clean air forms a highly efficient “sterile air curtain” or “clean zone” directly above the operating table, the patient and the surgical team. All particles released by personnel (for example, exfoliating skin particles) or equipment are immediately picked up by the flow and removed from the area, preventing them from settling on open wounds or sterile instruments.

“Image 1: Diagram of the laminar flow in the operating room. It clearly shows the unidirectional flow of air from top to bottom, displacing pollution from the critical zone.

Laminar Flow Velocity: Optimal values and their significance for effective protection

To ensure the stability and maximum efficiency of the laminar flow, its speed is extremely important. According to strict medical standards and recommendations from Klimor, the optimal air velocity in the laminar flow zone ranges from 0.2 to 0.3 m/s.8 Maintaining a velocity of at least 0.2 m/s is critically important to prevent turbulence and ensure unidirectional displacement of pollutants.

It is important to note that this low, controlled laminar flow velocity in the operating area differs from the air velocity in the main ducts of the ventilation system. The air velocity in the connecting pipes can reach 3 m/s and even 4-5 m/s in the main air ducts. However, if air were supplied to the operating room at such a high speed, it would lead to severe turbulence, noise and discomfort, completely negating the effect of laminar flow. The precise observance of the 0.2-0.3 m/s range is the result of advanced engineering developments aimed at creating a highly controlled and predictable air environment. This precision is critically important to prevent the re-uplift of already settled pollutants, which is key to achieving biosafety. This highlights that Klimor NSL laminar ceilings are not just devices for moving air, but complex systems designed to maintain a delicate balance of aerodynamics to ensure maximum sterility.

The Heart of Purity: HEPA H13 and H14 Filters

Explanation of the function of HEPA filters in trapping microbes and bacteria

Each laminar ceiling is based on a highly efficient air filtration system. HEPA (High-Efficiency Particulate Air) filters are not just filters, but a technological barrier capable of detaining up to 99.995% of the smallest particles, including bacteria, fungal spores, viruses, pollen and even the smallest dust particles that are not visible to the naked eye. These filters are the last and most important stage of air purification before it is supplied to the sterile area.

Filtration Classes: Differences between H13 and H14 and their effectiveness

Klimor NSL offers diffusers with filters of various classes that meet international standards. Classes H13 and H14 are most often used in medical institutions.:

HEPA H13: Provides 99.95% filtration efficiency for 0.3 micrometer particles (the most penetrating particle size, MPPS). It is a standard choice for many ISO 7 class clean rooms, for example, for other operating rooms or intensive care units.

HEPA H14: Offers an even higher level of protection with a filtration efficiency of 99.995% for 0.3 micrometer particles. H14 filters are a mandatory requirement for operating rooms of the highest purity class (ISO 5), such as operating rooms with laminar flows and burn chambers.

These filter classes comply with strict international standards such as PN-EN 1822-1:2019-05, which confirms their highest quality and reliability.

The importance of using certified filters and regular maintenance

The use of certified HEPA filters conforming to standards such as PN-EN 1822 and ISO 29463 is a prerequisite for ensuring sterility in medical institutions. This is not just a requirement, but a guarantee of safety and infection prevention.

Regular checking of the filters (for example, according to the differential pressure gauge, which indicates a doubling of the initial resistance) and their timely replacement are critically important. According to the requirements, ventilation systems in hospitals must be checked at least once every 12 months. Professional installation and validation of filters by qualified personnel is the key to their effective operation.

Table 1: Comparison of the effectiveness of H13 and H14 HEPA filters and their use in medical institutions

Characteristic of HEPA H13 HEPA H14

Filtration efficiency (for 0.3 microns particles) 99.95% 99.995%

Classification (according to PN-EN 1822-1) High-efficiency Ultra-high-efficiency

Typical room cleanliness class (according to ISO 14644-1) ISO 7 ISO 5

Examples of rooms in medical institutions are Other operating rooms, intensive care units, postoperative rooms, operating rooms with laminar flow, burn rooms, sterile laboratory areas

The choice of filtration class directly depends on the required cleanliness class of the room, which is determined by the specifics of the medical procedures performed in it. For example, for operating rooms where the highest level of sterility is required (ISO class 5), H14 filters must be used. This underlines that the decision to choose a filter is not just a technical one, but a strategic one, determined by strict sanitary standards and infection control needs.

The Principle Of Positive Pressure: An Invisible Barrier Against Contamination

A detailed explanation of why the air supply prevails over the exhaust in aseptic rooms

The principle of “positive pressure” is applied to ensure maximum sterility in operating rooms and other aseptic rooms (for example, intensive care units requiring maximum air cleanliness). This means that the volume of clean air supplied to the room is slightly higher than the volume of the air removed.

This excess creates a small but constant pressure inside a clean room compared to adjacent, less clean areas (for example, corridors or preoperative rooms). Maintaining a minimum pressure drop, for example, of at least 5 Pa, is critical for system stability.

How does this prevent the ingress of polluted air from neighboring areas

Due to the maintenance of positive pressure, the air naturally always moves from a cleaner area (operating room) to less clean rooms, and not vice versa. This effect creates an invisible but extremely effective air barrier that prevents dust, bacteria, viruses and microbes from entering the sterile environment of the operating room, even when the doors are opened.

The positive pressure principle is part of a comprehensive approach to pollution control that goes beyond a single operating room. It involves creating a “pressure cascade” throughout the surgical unit, where the cleanest areas have the highest pressure, and the less clean areas have a gradually lower pressure. This ensures a constant movement of air from sterile areas to common areas, effectively displacing pollution. To maintain these critical parameters, the ventilation system must operate continuously, which requires high reliability of equipment and careful design.

Effective Removal Of Impurities: The Location Of The Hood

Explanation of the optimal location of exhaust vents for removing polluted air

To ensure maximum laminar flow efficiency, exhaust vents in operating rooms are strategically located at the bottom of the walls. This provides a “washing out” effect: clean air coming from above pushes dirt down and to the perimeter of the room, where they are immediately removed by the exhaust system.

Some modern approaches to ventilation design in operating rooms also provide for partial removal of air from the upper zone (up to 40% of the total volume of the hood) in order to capture any rising particles or heat, although the bulk of contamination (60%) is removed from below, at a level of 0.6 m from the floor. This balanced distribution of exhaust vents ensures the most complete removal of all types of contaminants from the work area.

“Image 2: The principle of organizing air flows in an operating room with a laminar ceiling and a strategic hood location (at the bottom of the walls).

The strategic location of the exhaust vents is an integral part of the overall cleanroom engineering system. It is not a random choice, but is a direct consequence of the principle of unidirectional laminar flow. This demonstrates that a laminar ceiling is not just a separate device, but a key component of a carefully designed and integrated ventilation system. Understanding these subtleties in the design and implementation of exhaust systems allows us to ensure optimal performance and achieve the required purity classes, emphasizing the company’s deep technical knowledge and experience in creating integrated solutions for medical institutions.

Klimor NSL: Advanced Laminar Diffusers for Medicine

Presentation of the Klimor NSL series

Klimor, a leading Polish manufacturer of ventilation and air conditioning equipment, is a recognized leader in high-quality systems for the most demanding applications, including medical facilities.The 15 series of NSL laminar flow diffusers are highly specialized devices designed to ensure the highest standards of air cleanliness. These diffusers are the heart of the clean air system, providing sterile air to operating rooms, intensive care units and other protected areas where strict microbiological and dust cleanliness control is required.

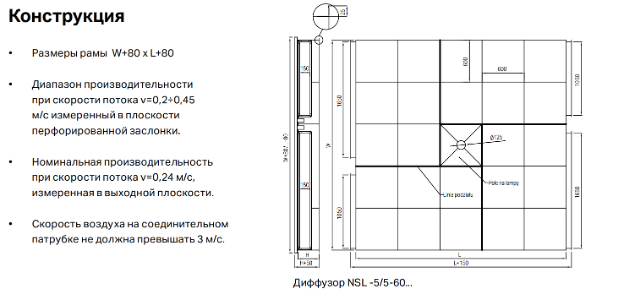

Design and features of Klimor NSL

Klimor NSL diffusers feature a sophisticated design that ensures maximum efficiency and reliability.:

● Reliable and hygienic: The body of NSL diffusers is made of sealed stainless steel with smooth inner surfaces. This material provides high resistance to aggressive disinfectants, which makes it easy to clean and prevents the accumulation of impurities.8

● Integrated filtration: Diffusers are equipped with reliably integrated absolute HEPA filters. Class H13 filters are installed as standard, and at the request of the customer, H14 or E11 filters can be installed.8 The elements pressing the filters to the housing ensure tightness and reliability of fastening.8

● Efficient laminator: The diffuser laminator consists of an easily removable perforated metal flap (optional fabric laminator). Its design ensures uniform air distribution and the formation of a stable laminar flow.8

● Monitoring and validation: For ease of operation and monitoring, diffusers are equipped as standard with nozzles for measuring pressure differences (allowing monitoring of filter contamination) and nozzles for measuring aerosol concentration (for system validation). These functions are critical to maintaining cleanliness standards.8

● Convenience for the operating room: The diffuser design provides a special place for the passage of the base of the shadowless operating lamp, completed with a split masking cover. This ensures seamless integration into the design of the operating room and the maintenance of tightness.8

Key Advantages of NSL diffusers

● High reliability and durability: Klimor NSL diffusers are designed and manufactured to meet the strict requirements of hospital and cleanroom standards, ensuring their high reliability and long service life.8

● Uniform and stable flow: A characteristic feature of NSL diffusers is a uniform air flow at an optimal speed, which is the key to effective protection against contamination.8

● Low flow resistance: The design of the diffusers ensures low flow resistance, which minimizes the load on the ventilation system and promotes energy efficiency.8

● Long filter life: With proper operation and regular monitoring of the filter condition (for example, according to the differential pressure gauge), the service life of absolute HEPA filters in the diffuser can reach 3 years.8

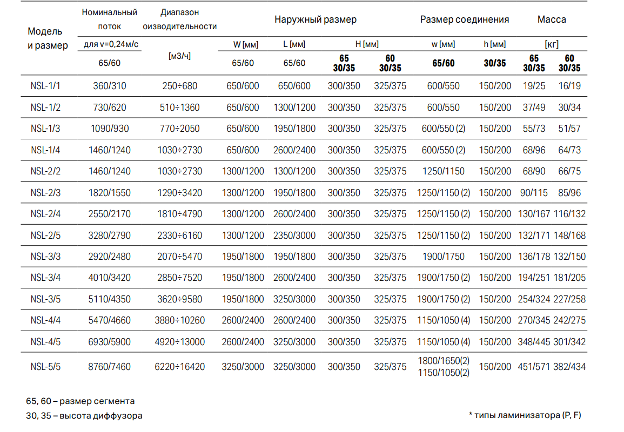

Klimor NSL Product Range: A Wide Range of Solutions for Any Task

The Klimor NSL series offers a wide range of capacities from 250 to 16,500 m3/h and includes 14 basic sizes.8 This allows you to choose the optimal solution for operating rooms of any size and configuration. Models range from compact NSL-1/1 to large NSL-5/5, providing flexibility in design and installation. It is possible to choose the filter class (H13 or H14), the type of laminator (perforated sheet metal or fabric) and the presence of a curtain, which allows you to accurately adapt the diffuser to the specific requirements of the project.8

Table 2: Examples of Klimor NSL Laminar Diffuser Models (Excerpt from the Catalog)

Note: A complete model catalog and detailed technical specifications are available on request.

● This means that the purchase of a laminar ceiling is not a one–time purchase, but an investment that requires constant support. Thus, the company supplying such equipment should be ready to offer not only sales, but also a full range of after-sales services: scheduled filter replacement, regular system checks and validation of its operation. This approach ensures continuous compliance with sanitary standards and maximizes the effectiveness of the client’s investments.

Climate PROF Kazakhstan LLP: Your Reliable Partner in Ensuring Cleanliness

Climate PROF Kazakhstan LLP is the official and exclusive representative of the Polish Klimor plant in Kazakhstan. This partnership guarantees our customers access to original, high-quality equipment that meets the strictest European and international standards. The company does not just supply equipment; it offers comprehensive solutions for creating and maintaining sterile environments in medical institutions.

The successful implementation of a laminar ceiling installation project is a complex process that requires in–depth knowledge and experience. Our team of specialists is ready to provide a full range of services.:

● Expert advice: Assistance in determining the optimal cleanliness class for your premises and selecting suitable Klimor NSL models based on the specifics of your medical facility and applicable regulations (for example, ISO 14644-1 standards and national SanPiN).11

● Professional installation: Qualified installation of equipment in strict accordance with manufacturer’s instructions and industry standards.2

● Commissioning and validation: Carrying out all necessary measurements and tests to confirm the system’s compliance with the declared parameters and standards of cleanliness. This includes checking the tightness of the filters and the uniformity of the filter material.8

● After-sales service: Regular inspection, maintenance and timely replacement of filters, which is critical to maintain efficiency and extend the service life of the system.8

Understanding the complexity of cleanroom systems, including specific standards, pressure management, and installation and validation requirements, allows Climate PROF Kazakhstan LLP to go beyond simply selling equipment. The true value of the company’s offer lies in its ability to provide a full range of services: from initial consultation and precise design to professional installation and ongoing maintenance. Such an integrated approach not only ensures compliance with all standards and long-term efficiency of the system, but also positions Climate PROF Kazakhstan LLP as a strategic partner capable of solving complex tasks in the field of ventilation and air cleanliness for medical institutions. This allows the company not only to sell products, but to build long-term relationships with customers based on trust and proven competence.

Conclusion: Investing in Security is Investing in the Future

In modern healthcare, where patient safety is the highest priority, Klimor NSL laminar ceilings are an indispensable solution. They ensure air sterility in critical areas, effectively protecting patients from bacteria and germs during surgery. Thanks to unidirectional air flow, highly efficient HEPA filters (H13, H14) and the principle of positive pressure, these systems create a reliable barrier against nosocomial infections.

By choosing Klimor NSL, medical institutions in Kazakhstan invest in reliability, advanced technologies and, most importantly, in the safety and health of their patients. This is not just the purchase of equipment, but a strategic decision that ensures compliance with the highest standards of air cleanliness, reduces health risks and strengthens the reputation of the institution.

Do not miss the opportunity to ensure the highest level of cleanliness and safety in your medical facility. Contact Climate PROF Kazakhstan LLP today for an individual consultation and selection of the optimal solution designed specifically for your needs. Our experts are ready to answer all your questions and help you create a truly sterile environment.

Catalog on our website — Klimor NSL

Installation instructions — Klimor NSL